Usamos a farinha para uma infinidade de pratos e elaborações de produtos de padaria e pastelaria, mas o que sabemos sobre as diferentes farinhas? Como é obtido em cada caso? Qual é o mais conveniente para cada preparação? E para a nossa saúde? Neste artigo vamos responder a estas perguntas e dizer tudo o que você precisa saber sobre as diferentes farinhas

O que é farinha?

Farinha é o pó fino que é obtido a partir de cereais moídos e outros alimentos ricos em amido. Você pode obter farinha de cereais diferentes. Embora o mais comum é a farinha de trigo, também feita de farinha de outros cereais como o centeio, cevada, aveia, milho, arroz ... e há também outros tipos de farinhas provenientes de outros alimentos, tais como legumes (ervilhas, soja), frutos secos, mandioca, etc.

A farinha pode conter mais ou menos grãos inteiros, dependendo se mais ou menos farelo e germe são descartados. A proporção de grãos inteiros que é usada para obter a farinha é chamada de grau de extração . Quando falamos de um grau de 90% de extração, seria uma farinha que contém 90% do cereal completo e 10% de farelo e germe foram descartados. Portanto, uma farinha integral seria uma farinha com 100% de extração.

Que partes podemos diferenciar em um grão de cereal?

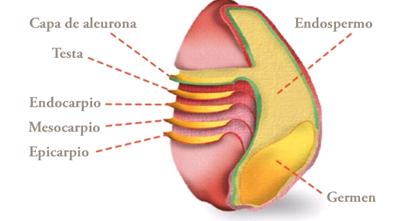

Para ter uma idéia mais clara do que seria todo o cereal, veremos quais partes podemos diferenciar em um grão de cereal.

Nos cereais podemos diferenciar 3 partes: farelo, germe e endosperma.

Salvo: é a capa do cereal. É formado por sua vez por 2 partes:

- Pericarpo: é a camada externa e é formado pelo epicarpo, mesocarpo e endocarpo.

- Cutícula: envolve a semente e é formada pela camada de tesla e aleurona.

O farelo é rico em vitaminas do complexo B e minerais.

Endosperma: envolve o germe ou embrião e fornece os nutrientes necessários para o seu desenvolvimento.

O endosperma contém uma grande quantidade de carboidratos, especialmente amidos e proteínas, e em menor grau vitaminas e minerais.

Germe: É a parte da semente que germina e dará origem a uma nova planta.

O germe contém proteínas de alta qualidade, vitaminas do grupo B, vitamina E, minerais e lipídios que podem ser extraídos na forma de óleos vegetais.

Trituração ou trituração de trigo

A moagem de trigo consiste em reduzir o tamanho do grão através de moinhos de rolos. Primeiro, o farelo e o germe são separados do endosperma e então o último é reduzido até que a farinha seja obtida. O objetivo da moagem é maximizar o rendimento da farinha com o teor mínimo de farelo.

O processo de moagem consiste em dois estágios de quebra e redução, a moagem é feita gradativamente, obtendo-se em cada estágio uma parte de farinha e outra de partículas maiores. Entre a fase e a fase de moagem, o produto moído é triado e a farinha é purificada.

- Esmagamento: O grão de trigo, após ser limpo e condicionado, é passado pelo primeiro conjunto de rolos a serem esmagados.

- Triagem: A função de peneirar ou peneirar é separar o produto nas três principais frações: farelo, sêmola e germe.

- Purificação : Após o esmagamento, o farelo é eliminado e a sêmola é classificada por espessuras através de peneiras e purificadores.

- Redução: O objetivo da redução é moer a sêmola e a sêmola purificada e transformá-las em farinha. Ele reduz as partículas de sêmola a uma finura de farinha também remove algumas partículas de farelo e germe que podem permanecer, esta operação é realizada com uma peneira. Este processo é realizado várias vezes até que a maior parte da semolina extraível seja eliminada.

Moagem de trigo mole: farinha

trigos macios são esmagados e prensados em farinha, que separa o farelo e o germe endosperma. O grão esmagado por um processo de peneiração, e, em seguida, as partículas de endosperma puro, sêmola e de sêmola são comprimidas e reduzidas em tamanho até a farinha obtida é classificada de acordo com o seu tamanho. Esta farinha será passada por peneiras.

Moagem de trigos duros: sêmola

Em moinhos de sêmola não esmagar o grão mas não cortar camadas de ir progressivamente reduzindo o seu tamanho até que todas as partículas têm o mesmo tamanho. Por peneiração as partículas por sua colorido mais escuro ou peso não são adequados para a produção de sêmola são removidos.

Branqueamento de farinha

A farinha tem um pigmento amarelo composto por 95% de xantofila ou seus ésteres. pigmento natural branqueamento trigo endosperma por oxidação ocorre rapidamente quando a farinha é exposta ao ar, mais lenta é a massa de farinha é exposta, e pode ser acelerado por meio de tratamento químico utilizando agentes de branqueamento baseados principalmente em compostos clorados.

Classificação de tipos de farinhas:

A classificação mais utilizada na Europa, baseia-se na quantidade de glúten ou proteínas que a farinha possui e, de acordo com isso, podemos encontrar:

- Farinha extra forte: É caracterizada por ter uma alta porcentagem de proteínas (acima de 13%). É obtido a partir do trigo duro e é utilizado principalmente para a preparação de massa.

- Farinha forte: A porcentagem de proteína está entre 10 e 12%, e é usada para fazer pão.

- Farinha Fraca: Tem uma porcentagem de proteína entre 7 e 9%. Eles são usados para confeitaria e biscoitos, e não é adequado para fazer pão porque eles não mantêm sua estrutura firme.

Outra classificação mais usada na América é aquela baseada na numeração por "zeros", na qual os zeros determinam o grau de pureza da farinha e assim temos farinha de zero (0), dois zeros (00), três zeros (000) ) e quatro zeros (0000).

- A farinha de 0 são mais grossos, mais impurezas e qualquer grão restante. Eles são menos refinados e são usados para elaborações mais espessas.

- As farinhas de 00 e 000 são usados para fazer pão, por seu alto teor de proteína, especialmente o glúten que permite que as massas de moldar e boa fermentação é conseguido sem perder suas peças de forma.

- A farinha 0000 é mais refinada e mais branca, tendo pouca formação de glúten não é um bom recipiente de gás e os pães não mantêm a forma. É usado em pastelaria, confeitaria, massa folhada, etc. e massas que precisam ser leves.

A equivalência entre as duas classificações seria a seguinte:

- Farinha 0 = farinha de grande força

- Farinha 00 = farinha de força média

- 000 farinha = farinha solta

- Farinha 0000 = farinha muito solta

Às vezes encontramos denominações ou preparações comerciais como:

- farinha forte: Esta farinha é o trigo vem e é assim chamado por causa da força que deve ser feito para amassar, é rica em glúten mantendo assim a quantidade de água e forma consistente e massas elásticas. É usado principalmente para fazer massas, pão e algumas receitas de pastelaria.

- Farinha Tempura : É amplamente utilizada para preparações japonesas e é perfeita para massa. É composto de farinha de trigo, amido, fermento e pó de gema de ovo.

- Lixiviar ou assar farinha : É um tipo de farinha a que é adicionado um produto de fermento, como o fermento em pó, que serve para aumentar o volume dos produtos que vão ser assados.

Em relação a se a farinha é ou não passável, a farinha de trigo pode ser considerada como pão, incluindo espelta e kamut, centeio e milho, menos farinha de panificação, farinha de aveia, soja, teff e farinha de trigo sarraceno. farinha sem pão, arroz, farinha de quinoa ou grão de bico.

Sêmola e Semolina

Quando falamos de semolina , estamos falando de farinha grossa, isto é, pouca terra que pode vir do trigo ou de outros cereais. Normalmente vem do trigo duro e é usado para fazer macarrão (ravióli, macarrão, macarrão e outros). Se a moagem é algo mais fino, recebe o nome de semolina.

A sêmola é o principal produto de moagem grosseira e grãos de farinha de trigo produzidas por moagem comum.

Que farinha preferimos para sermos os mais saudáveis?

A farinha mais desejável é o integral em que o grão integral é moído. O principal problema dessa farinha no nível industrial é que sua vida útil é menor porque os lipídios contidos no germe ficam facilmente rançosos, então, idealmente, ele é moído na hora. Deve ser levado em conta que, infelizmente, muitas vezes quando compramos pão integral não estamos comprando pão feito com farinha integral, mas farinha branca tem sido usada e farelo é adicionado, por isso a cor é mais escura. Se quisermos verificar se a farinha integral foi utilizada, devemos verificá-la na sua lista de ingredientes.

Leave a Reply

Your email is safe with us.